Rope access techniques have revolutionized the way we approach high-altitude work, allowing professionals to access difficult-to-reach locations with ease. However, the safety of rope access operations heavily relies on the integrity of anchor points. When it comes to purlin-mounted anchor points, there have been instances where these vital components were incorrectly installed, leading to compromised safety measures. In this blog post, we will explore the potential hazards posed by improperly engaged purlin-mounted anchor points and emphasize the importance of adhering to proper installation guidelines.

Understanding Purlin-Mounted Anchor Points

Purlin-mounted anchor points are designed to provide a secure connection between a worker’s rope and the supporting structure. These anchor points are usually installed on purlins, which are horizontal structural members in a building’s roof or wall structure. Their proper installation is crucial to ensuring the safety and stability of rope access operations.

The Dangers of Incorrect Installation

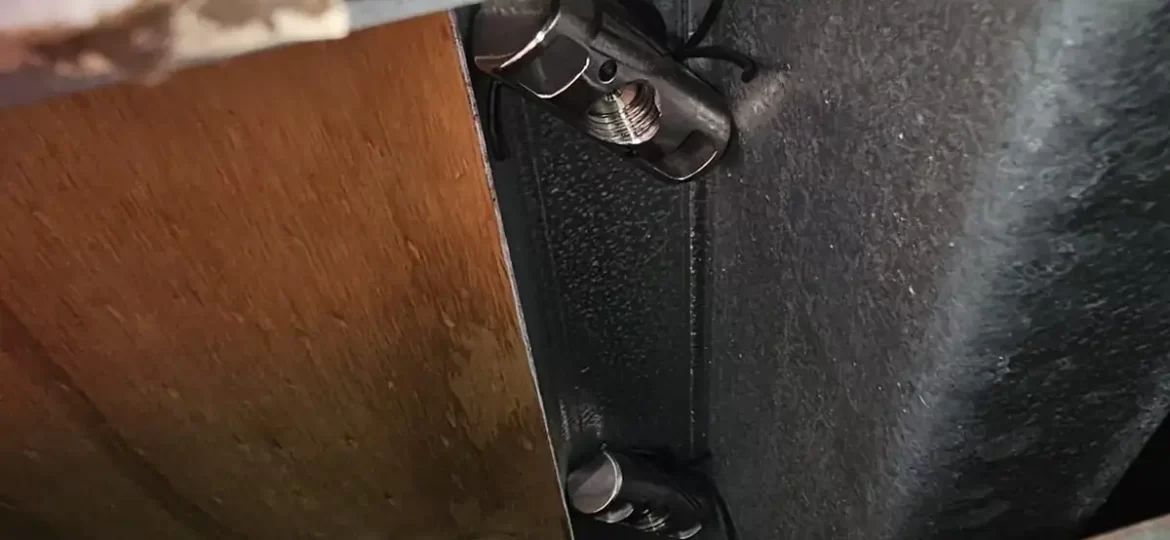

In certain unfortunate instances, purlin-mounted anchor points may be incorrectly installed, leading to minimal thread engagement. This occurs when the anchor is not fully engaged into the mounting bar, leaving only a fraction of the threads providing support. Such incorrect installations pose significant safety risks for rope access technicians:

- Reduced Load Capacity: The minimal engagement of threads significantly reduces the anchor’s load-bearing capacity. Under stress, the anchor point may fail, risking the lives of workers suspended on ropes.

- Unreliable Support: Improperly installed anchor points are prone to movement and loosening over time, compromising the stability required for safe rope access work.

- Anchor Point Failure: The combination of reduced load capacity and unreliable support can result in a catastrophic anchor point failure, leading to falls and serious injuries or fatalities.

- Hidden Danger: Superficial inspections may not immediately reveal the faulty installation, making it imperative to carry out regular, thorough inspections to identify potential risks.

Preventing Safety Risks: Adhering to Best Practices

To avoid the potential safety hazards associated with incorrectly installed purlin-mounted anchor points, rope access professionals and employers must take the following precautions:

- Certified Installation: Always ensure that anchor points are installed by qualified and certified professionals with expertise in rope access systems.

- Inspections and Maintenance: Regularly inspect all anchor points to verify correct engagement and structural integrity. Perform maintenance and necessary repairs promptly.

- Quality Equipment: Use high-quality and tested anchor points that comply with industry standards and regulations.

- Employee Training: Train all rope access technicians on proper anchor point inspection procedures and safe work practices.

- Risk Assessment: Conduct thorough risk assessments before commencing any rope access work, and ensure potential hazards related to anchor points are adequately addressed.

Conclusion

Rope access techniques have undoubtedly transformed the way we approach challenging tasks at great heights. However, safety must always remain the paramount concern in such operations. The potential risks associated with incorrectly installed purlin-mounted anchor points demand vigilance and adherence to best practices. By investing in certified installation, regular inspections, and employee training, we can significantly mitigate safety hazards and ensure that rope access work remains a safe and effective solution for high-altitude tasks. Remember, the lifeline of every rope access technician is the reliability of their anchor points!